The Main Principles Of Roar Solutions

The Main Principles Of Roar Solutions

Blog Article

All about Roar Solutions

Table of Contents3 Easy Facts About Roar Solutions ShownRoar Solutions Can Be Fun For EveryoneRoar Solutions Can Be Fun For AnyoneFacts About Roar Solutions RevealedThe Best Strategy To Use For Roar Solutions

The course and is intended for Electrical contractors and Electrical Designers to understand their demands in dangerous area classification, explosion-protection strategies, equipment installation needs, assessments and procedures for malfunctions and upkeep. Ex and HA concept and useful are covered with an emphasis on assessment and testing - eeha training. Program cost: $1,100 AUD (GST FREE) If you have previously done the EEHA training course and have worked in an associated market you are qualified to do the EEHA correspondence courseThere is an RPL (acknowledgment of previous learning) process and requires you to confirm your job background verbally throughout the course and in composing previous to beginning to be eligible. EEHA REFRESHER = Acknowledgment of Prior Understanding: The employer/officer of the company (Supervisor) and or pupil will give a detailed, authorized, letter of the experience the worker acquired maintained throughout the previous three yearsStudent will prove their job history vocally throughout the training course.

(https://www.video-bookmark.com/bookmark/6634779/roar-solutions/)

And here's some impressive content. It's very engaging.

Some Known Incorrect Statements About Roar Solutions

You can after that move on to the Core Specialist and after that the much more innovative CompEx courses as listed here. Picking the proper degree of credentials and the relevance of completing suitable pre-course knowing is something that both us and the neighborhood training provider advertise heavily. This guarantees that candidates have the greatest possibility of passing their training course very first time.

Please keep in mind that the recertification of components aside from the Ex01-04 is attained by embarking on the original credentials once more to gain your Certificate of Core Proficiency for a more 5 years. Click here to see the different levels. Whether pre-learning is done with analysis, doing, or paying attention, by placing in the time in advance of the program, learners can comprehend the level of knowledge that the course trainer expects all candidates to have when they get here for the very first day of knowing.

Roar Solutions for Dummies

We will be introducing an interactive website tool that will aid you browse the courses and assist select the best one. View this space for updates.

Training courses are offered year-round, so do not miss the possibility to raise your one-upmanship. All harmful area courses, training and evaluation is aligned to the demands of the pertinent AS/NZS Criteria. AS/NZS Requirements books are available for purchase with each program. Book online to obtain 10% off useful link the conventional training course rate.

3 Easy Facts About Roar Solutions Explained

Shown evidence of competency in installation planning and electrical design for standard (i.e. non-explosion protected) circuits and installments is also called for. You have to offer a comprehensive CV and examples of style records. Discover more about these requirements at the Extend Training website or offer us a telephone call if you have any questions.

In industries where the setting can present unsafe conditions, such as mining, oil and gas, and chemical manufacturing, safety is vital. This is where Electric Tools for Hazardous Areas (EEHA) enters into play. Understanding EEHA is important for professionals working in these industries to guarantee that all procedures involving electrical tools are performed safely.

A harmful location is specified as any type of location where the environment contains combustible gases, vapours, haze, or dust in sufficient quantities to trigger a fire or explosion. The nature of these compounds implies that standard electric tools could ignite the ambience under normal operating conditions. Because of this, unique precautions need to be taken to use equipment that is developed and accredited to be safe in these settings.

The Definitive Guide for Roar Solutions

These standards guarantee that all devices appropriates for the certain course of hazardous area in which it is made use of. In Australia, the essential standards include: AS/NZS 60079 Collection: This collection covers the certain demands for building and construction, screening, and marking of electric devices intended for use in eruptive environments. AS/NZS 3000 (Electrical Wiring Rules): This consists of details areas that deal with the installment and upkeep of electric systems in hazardous areas.

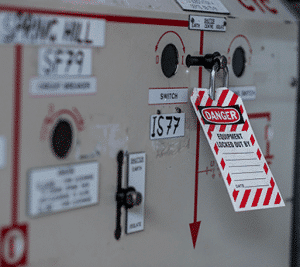

Compliance with these criteria is not just a legal need; it is vital for making sure the safety and security and effectiveness of procedures in dangerous atmospheres. EEHA includes a variety of components and practices made to minimise the risk of ignition in harmful locations. These consist of: Fundamentally Safe Equipment: Devices designed to restrict the electrical and thermal power offered for ignition.

Pressurisation and Purging Systems: Used to stop the development of an eruptive environment within an enclosure by utilizing a safety gas. Cord Glands and Sealing Fittings: Special fittings that protect against the flow of gases, vapours, or fires through electrical channels. Routine Inspections and Upkeep: Making sure that all equipment is preserved according to the supplier's specifications and requirements needs.

Educating makes sure that personnel know the risks, comprehend the details demands of the tools and installments, and are proficient in applying ideal methods for installation, upkeep, and assessment. Plumpton Group provides thorough EEHA training programs tailored to fulfill the needs of markets running in harmful locations (eeha). These programs cover: EEHA Setup and Maintenance: For electric workers in charge of establishing up and preserving risk-free electrical installments in unsafe locations

Report this page